Polyurethane Packaging: Effective Protection Solution

Introduction to Polyurethane Packaging

Polyurethane packaging is a flexible, lightweight, and highly resilient material solution commonly used in the packaging industry. Recognized for its versatility, this material has proven particularly effective for protecting delicate and fragile items. Originally known for applications in furniture and bedding, polyurethane has carved a niche in packaging due to its ability to cushion and protect multiple items in transit. This type of packaging is ideal for industries dealing with sensitive components, such as electronics, medical supplies, and ceramics. Polyurethane foam inserts, with their customizability, have become an essential element in the protective packaging industry.

Benefits of Polyurethane Packaging

Polyurethane packaging offers a range of benefits, making it a top choice for companies aiming to ensure their products’ safe and intact delivery. Here’s a closer look at the advantages that make polyurethane foam inserts invaluable in packaging solutions:

1. Lightweight and Flexible

One of the primary benefits of polyurethane packaging is its lightweight nature, which reduces shipping costs while maintaining excellent protective qualities. Unlike many other packing materials, polyurethane foam can be cut and shaped to snugly fit products of various sizes and shapes, providing a custom fit. This adaptability is especially beneficial for companies shipping delicate goods that require extra care.

2. Shock Absorption and Resilience

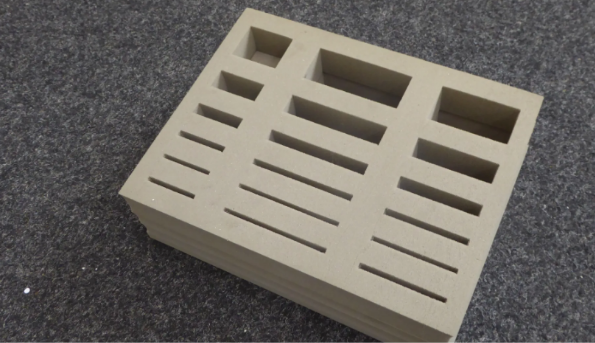

Polyurethane foam inserts are resilient, meaning they return to their original shape after absorbing impact. This feature makes them highly effective for shock absorption, ensuring that fragile items like electronics and ceramics are protected during transit. The foam’s structure, often designed with “egg box” or convoluted forms, contains numerous peaks and troughs, which help hold different products securely, minimizing movement and reducing damage risk.

3. Dust-Free and Clean Packaging

Dust and contaminants can harm sensitive products, such as electronics or medical equipment. Polyurethane foam offers a clean, dust-free packaging solution, keeping products free from particles that could otherwise compromise their integrity. This characteristic is critical for packaging items with strict hygiene standards, like those in the medical field.

4. Customizable Density and Colors

Polyurethane packaging can be customized not only in size and shape but also in density and color. This versatility allows businesses to choose the most suitable foam type for their products. Higher density foam provides additional rigidity, while lower density foam offers softer, more flexible support. Color options can also be beneficial for branding or categorizing products based on packaging colors.

Applications of Polyurethane Foam Inserts

Electronics and Computing

Electronic components and computing devices are often fragile and highly sensitive to impact. Polyurethane foam inserts are ideal for creating custom compartments in packaging, which secures each item within its own recess. This reduces the risk of damage due to movement during transit.

Medical Equipment

The medical industry requires packaging that is both protective and hygienic. Polyurethane foam provides a dust-free solution that meets the industry’s stringent requirements, making it an excellent choice for medical devices, equipment, and fragile tools.

Jewelry and Ceramics

Jewelry and ceramics are highly delicate and vulnerable to damage if not packed correctly. Polyurethane foam inserts can be designed to hold each piece individually, preventing any contact with other items. This ensures that jewelry, ceramics, and other fragile items are shipped safely.

Industrial Components

In the distribution of mechanical and industrial components, the secure transportation of parts is crucial. Polyurethane foam packaging provides a tailored solution for each component, reducing the risk of loss or damage. The material’s flexibility and resilience make it suitable for items that may be heavy but still require careful handling.

Comprehensive Packaging Solutions: More Than Just Foam

At Advanced Protective Packaging (APP), the company behind these innovative solutions, the approach to polyurethane packaging extends beyond the foam itself. They provide complete packaging solutions, including boxes and cartons tailored to fit the foam inserts. This combined solution allows businesses to order all packaging components from a single source, streamlining the procurement process and reducing paperwork. Here’s how their comprehensive approach benefits clients:

- Streamlined Supply Chain: Ordering packaging fitments and cartons from one supplier simplifies logistics and minimizes administrative burdens.

- Optimized Design Process: APP’s design team ensures that the packaging fitment matches the carton’s strength, providing the most efficient protection for products.

- Ancillary Packaging Products: Besides foam inserts, APP also offers other packaging products such as tape and bubble wrap, enabling clients to access a full spectrum of protective packaging needs.

Advanced Protective Packaging: Industry Expertise and Customer-Centric Approach

Advanced Protective Packaging (APP) has established itself as a leading UK-based provider of bespoke polyurethane packaging solutions. With nearly 40 years of experience, APP was founded in 1986 by Brian Garsden, whose goal was to position the company as a national leader in protective packaging. Under the management of Mark Hollingsworth, the founder’s son-in-law, APP continues to uphold the vision of delivering high-quality and customizable solutions tailored to each client’s needs.

Read also: Foam Conversion: An In-Depth Look at Its Processes and Benefits

Operating across various sectors, APP serves industries as diverse as medical, automotive, electronics, sports, and entertainment. Their success is attributed to a highly knowledgeable team and an extensive range of materials, including polyurethane, polystyrene, and polyethylene foams. By offering products that combine advanced material performance with bespoke design, APP ensures optimal product protection and client satisfaction.

Why Choose Polyurethane Foam Inserts for Your Packaging Needs?

Polyurethane foam inserts offer a superior level of customization and protection, making them the optimal choice for businesses that prioritize safe and cost-effective packaging. Some key reasons to choose polyurethane foam inserts from APP include:

Customized Protection

Each product is unique, and so are its packaging requirements. Polyurethane foam inserts are tailored to fit the precise dimensions of your product, offering a snug and protective fit that minimizes movement and absorbs impacts.

Cost-Effectiveness

Due to its lightweight nature, polyurethane foam reduces overall shipping costs, especially for bulk shipping. It is also reusable, allowing for multiple uses in packaging applications, further enhancing cost savings.

Brand Integrity

By providing quality packaging, companies ensure that their brand image remains positive. Damaged products due to inadequate packaging can harm brand perception, but with polyurethane foam inserts, clients receive their products intact and in pristine condition.

Environmentally Friendly Options

In addition to performance, polyurethane foam can be an environmentally conscious choice. As APP expands its product line, they remain committed to providing sustainable solutions that meet both client demands and environmental regulations.

How APP Delivers High-Quality Packaging Solutions

APP’s commitment to quality is evident in its comprehensive approach to packaging design. From consulting with clients on specific requirements to creating bespoke samples, APP’s team works closely with each client to ensure the packaging solution meets their precise needs. Their state-of-the-art manufacturing process involves cutting-edge technology that enhances product precision, durability, and aesthetic appeal.

Material Expertise and Product Range

APP offers a variety of materials beyond polyurethane, including polystyrene and polyethylene. Each material is chosen based on the client’s requirements, ensuring an ideal match between material properties and product needs.

Dedicated Sales and Support Team

APP’s experienced sales team provides guidance on packaging solutions, offering valuable insights and creating custom samples that allow clients to visualize the protection their products will receive. This hands-on approach ensures that clients are confident in their packaging choice before final production begins.

Conclusion: The Polyurethane Packaging Advantage

Polyurethane packaging is an ideal solution for businesses looking to protect their products while maintaining cost efficiency and environmental responsibility. Polyurethane foam inserts provide unmatched flexibility, resilience, and shock absorption, making them the perfect choice for industries such as electronics, medical, and industrial components. Through the extensive experience of Advanced Protective Packaging, clients benefit from customized solutions that cater specifically to their packaging requirements. With a customer-centered approach and a commitment to quality, APP continues to deliver outstanding results that protect products and enhance brand reputation.

By opting for polyurethane foam inserts from Advanced Protective Packaging, businesses can be assured that their products are not only protected but also presented professionally, reinforcing the value of each item shipped.